Rubber Linings:

Q: How do rubber linings protect industrial equipment?

A: Rubber linings act as a protective barrier against corrosion, abrasion, and chemical exposure. They provide a durable and resilient surface that shields industrial equipment from the detrimental effects of harsh operating conditions.

Q: What types of rubber materials are used in rubber linings?

A: The choice of rubber material depends on the specific application. Common materials include natural rubber, neoprene, nitrile, and specialty rubbers. The selection is based on factors such as chemical resistance, temperature, and abrasion requirements.

Q: How long do rubber linings typically last?

A: The lifespan of rubber linings varies based on factors like the type of rubber, the severity of operating conditions, and the quality of application. With proper maintenance, rubber linings can significantly extend the life of industrial equipment.

Water Jetting:

Q: What types of surfaces can be cleaned with water jetting?

A: Water jetting is versatile and suitable for cleaning various surfaces, including metal, concrete, and sensitive materials. It is effective in removing contaminants, coatings, and debris without causing damage to the underlying surface.

Q: How does water jetting contribute to environmental sustainability?

A: Water jetting is an environmentally friendly cleaning method as it typically uses water as the primary medium. It minimizes the use of chemicals and produces less waste compared to abrasive blasting or chemical cleaning methods.

Q: Can water jetting be used for surface preparation?

A: Yes, water jetting is an effective method for surface preparation. It removes rust, coatings, and contaminants, creating an ideal surface for the application of protective coatings. It ensures thorough cleaning without generating abrasive dust.

Abrasive Blasting:

Q: What types of abrasives are used in abrasive blasting?

A: Various abrasives can be used, including steel grit, aluminum oxide, and crushed glass. The choice depends on the specific application, desired surface profile, and the material being processed.

Q: Is abrasive blasting suitable for delicate surfaces?

A: While abrasive blasting is effective for tough surfaces, care must be taken with delicate materials. Adjustments in pressure and choice of abrasive can be made to ensure that the process does not cause damage.

Q: How does abrasive blasting enhance coating adhesion?

A: Abrasive blasting creates a textured surface profile on substrates, improving the adhesion of coatings. This profile allows coatings to bond more effectively, leading to increased coating durability and performance.

Coatings:

Q: What types of coatings do you offer?

A: We offer a range of coatings tailored to specific needs, including protective coatings, decorative finishes, anti-corrosion coatings, and specialty coatings.

Q: How long does it take for coatings to dry or cure?

A: Drying and curing times depend on the type of coating and environmental conditions. Our experts provide accurate timelines based on the specific coating applied and the project requirements.

Q: Can coatings be customized for specific colors or finishes?

A: Yes, our coatings can be customized to meet specific color and finish preferences. We work closely with clients to ensure that the coatings align with their aesthetic and functional requirements.

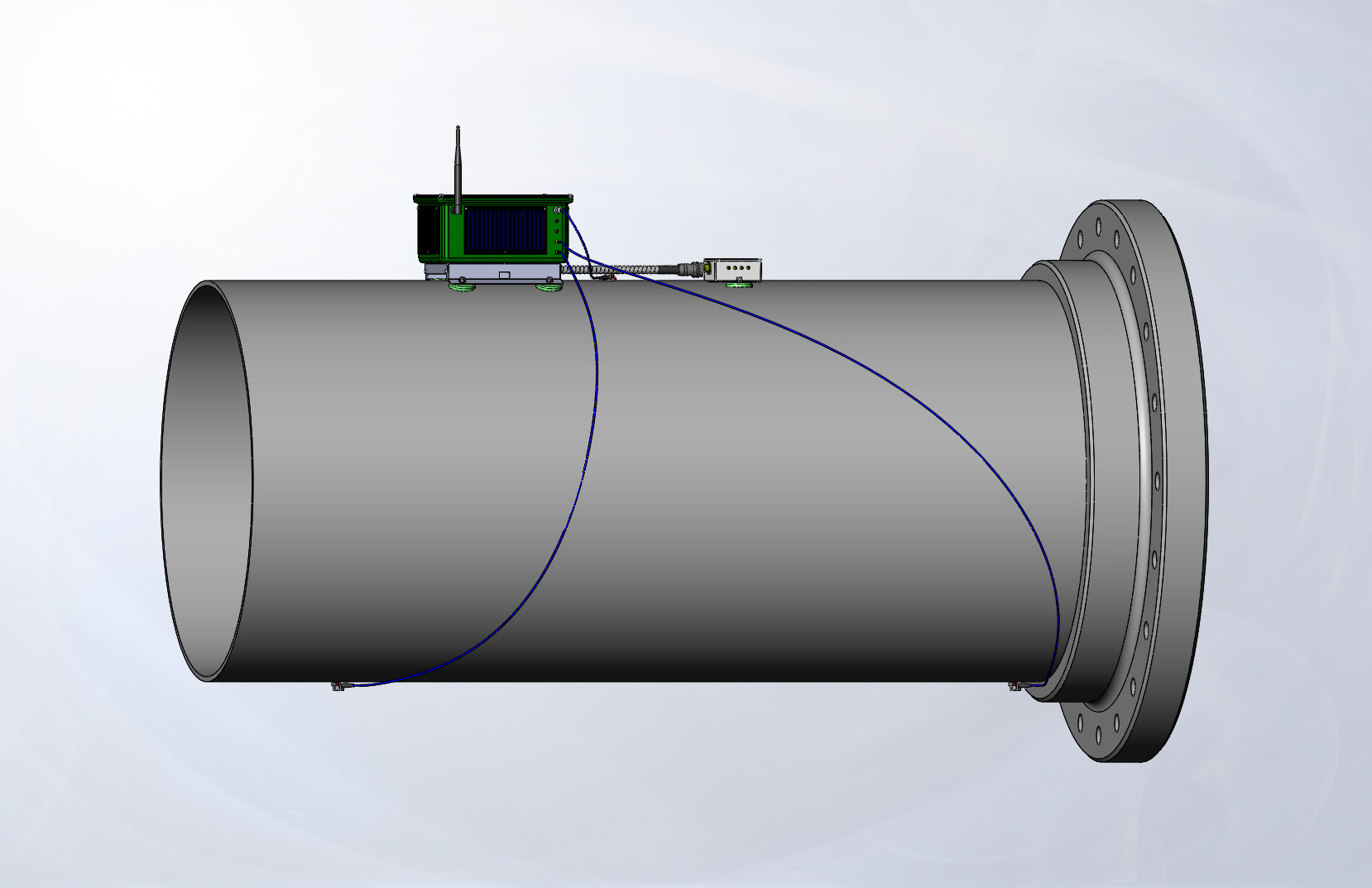

Inspection Services:

Q: Why are industrial inspections important?

A: Industrial inspections are crucial for ensuring the safety, reliability, and compliance of industrial assets. They help identify potential issues early on, allowing for proactive maintenance and risk mitigation.

Q: What types of inspection methods does Spence Corrosion utilize?

A: Our inspection services encompass various methods, including visual inspections, ultrasonic testing, hardness, holiday and more. The choice of method depends on the type of asset and the specific information required.

Q: How often should industrial inspections be conducted?

A: The frequency of inspections varies based on factors such as industry regulations, equipment criticality, and environmental conditions. Regular inspections are typically scheduled to identify and address issues in a timely manner.

Fiber Reinforced Polymers (FRP):

Q: What are the advantages of using Fiber Reinforced Polymers (FRP)?

A: FRP offers advantages such as high strength-to-weight ratio, corrosion resistance, design flexibility, and durability. It is suitable for applications in construction, automotive, aerospace, and other industries where lightweight, strong, and corrosion-resistant materials are essential.